Industrial Packaging: Protecting an Important Part of the Production Process

The Right Packaging And Supplier Largely Impact Both Your Operations And Your Sales

At DCP International we know industrial packaging. Whether you’re producing a single product or a million products, protecting your investment is key. We can customize our delivery program to meet your production needs, whether it is a daily delivery of multiple items or a weekly delivery of a single SKU.

An Industrial Packaging Program Specific To Your Needs

Not sure where to start? No problem, our team of experts can help identify the best options for your company.

With industrial packaging, protection is important. Whether you need a single wall corrugated stock box, with pre-shaped foam inserts for large-scale production, or foam-on-demand for your one-of-a-kind pieces we can be your one-stop packaging source.

Do you want to learn more? Explore your options below.

Products and Automation Solutions

Product

Blocking and Bracing

Prevent unwanted or damaging movement, while your products are in transit, with blocking and bracing. DCP International offers an array of air, paper, engineered foam, and pulp packaging solutions to help lock-in-place and cushion your product inside the box and in transit.

Product

Corrugate Containers

Corrugated cartons and products are a staple of product packaging for good reason. It is a relatively inexpensive, easy-to-use, recyclable product that can be cut to about any size or shape imaginable. These items can be custom designed or bought “off the shelf” in hundreds of stock sizes.

Product

Cushioning

Add stacking strength to any carton or container with corrugated partitions. Corrugated partitions are used in the packaging of various items including larger, heavier items, and also can be used to help support displays.

Product

Interleaving

When stacking items inside of a box, you run the risk of scratching, shifting and marring during the shipping process, especially if you don’t have the proper packaging. Interleaving protects your packaged goods, and we know just the right interleaving material matters to keep your product protected. With a wide range of solutions, DCP International can provide the proper stability, cushioning or surface protection for your needs.

Product

Mailing/Bagging

With e-commerce booming, more and more businesses are needing mailing and bagging packaging. Our diverse line of mailing and bagging solutions lets us help get your product ready for shipping. From stock and custom mailer products to automated systems we have the solutions that deliver.

Product

Shrink Systems

Give your products the look and protection they deserve with shrink sleeve packaging. Shrink sleeves are designed to fit cleanly around your product, giving you 360 degrees of tamper-evident protection and printing. Shrink sleeves are durable to wear and tear, and can easily be perforated to make them easy to remove.

Product

Surface Protection

Creating a product takes time, effort and money. The last thing you need when your job is done is for a scratch or dent to ruin your product and jeopardize your reputation. DCP International can help you protect your surface and shield it from all types of encounters in its journey from creation to consumer. Our solutions are tailored to your needs, whether you have to protect the surface, keep your edge or protect those in-between places.

Product

Thermal Ribbons

Your product’s packaging displays essential information. From barcodes to logos to expiration dates and batch numbers, your product data must be easily legible, identifiable, and traceable throughout the life cycle of your product packaging. Thermal transfer ribbons enable high fidelity printing and durability on a range of media including shipping tags, crates, signs, frozen food packaging, machine parts, and electronics

Product

Void Fill

Space inside a box may seem like a good thing, but too much space can allow products to shift and become damaged. That’s why it’s important to use appropriate void fill, to limit movement inside the box when shipping products. DCP International offers efficient and easy-to-use solutions whether you require an off-the-shelf material or On-Demand systems to integrate into your packaging line.

Product

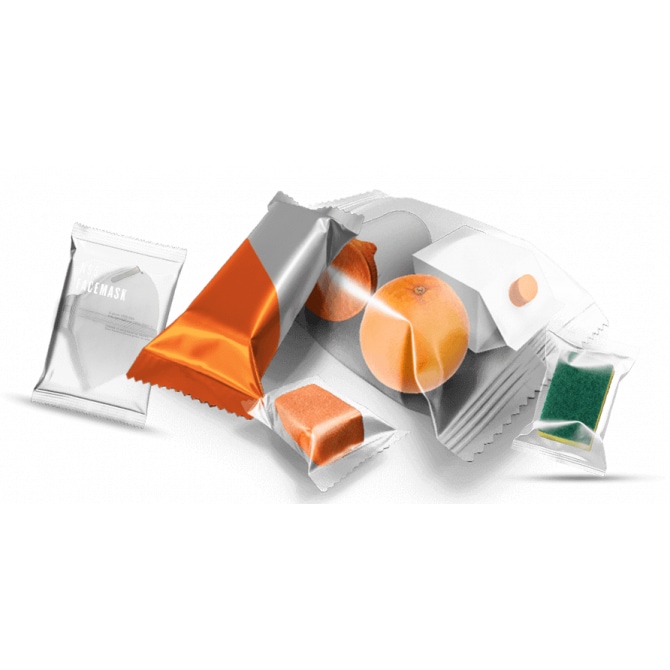

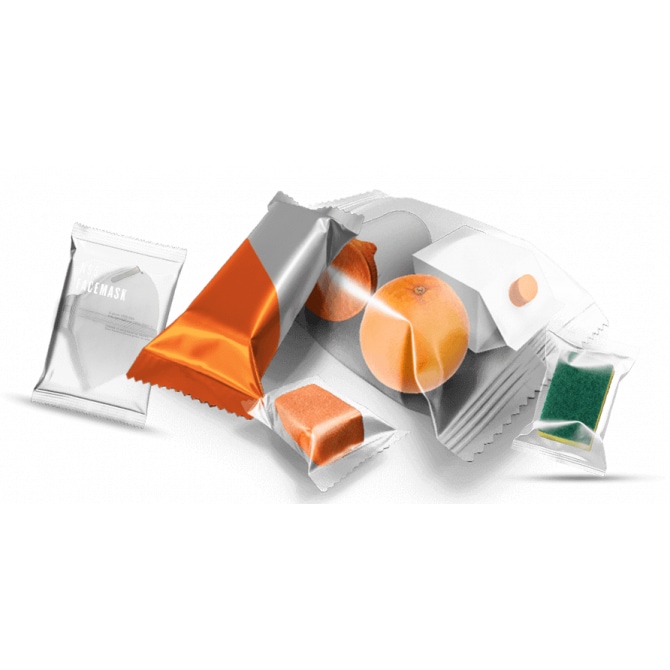

Wrapping

Wrapping processes like flow wrapping, encapsulate products in a thin layer of clear or printed film. This film is sealed to protect and contain contents. In some cases heat is applied to shrink the film, to minimize product shifting within the package and minimize the “tails” on the product.

Automation Solutions

Blocking and Bracing Automation

Fragile items, surface-critical parts, and heavy equipment are especially prone to freight-related damage. That’s why Pioneer works with a range of on-demand air, paper and foam packaging systems that are designed to protect against in-box or in-crate movement. Pioneer’s expert packaging team can help you to identify a solution that is cost-effective, and helps to prevent costly freight-related damage.

Automation Solutions

Cohesive Packaging Automation

Whether your business packages and ships ecommerce goods to consumers, or industrial parts for shipping and storage; cohesive packaging is an intelligent, cost-effective and versatile solution. Pioneer works with the widest line of cohesive materials and equipment in the industry, and can provide complete cohesive automation systems to increase your packaging efficiency.

Automation Solutions

Cushioning Automation

Whether you are shipping fragile items, surface-critical parts, or heavy equipment, we know that protecting your products from damage is important. That’s why Pioneer works with a range of on-demand air, paper and foam packaging systems, designed to meet the challenges of your business. We can help you to identify a solution that is cost-effective, and helps to prevent costly freight-related damage.

Automation Solutions

Carton/Tray Erector Automation

User-friendly, efficient, cost-effective case erecting and tray forming solutions are designed to increase your production’s productivity. We offer several machine options, including corrugated boxes, and end of line processes. Case erectors models are available for low, mid and high-speed production rates, operating at speeds up to 35 boxes per minute. These machines can help automate your production line or greatly improve your existing systems.

Automation Solutions

Mailing/Bagging Automation

Automated bagging systems are used in a wide range of industries to package small parts, manuals and finished goods. Bagging machines seamlessly integrate into your operations, through customized in-feeds and accessories. These machines scan, pack, seal and print labels directly onto bags for sorting and shipping. Our engineers will work with you to customize your bagging configuration to increase efficiency and output.

Automation Solutions

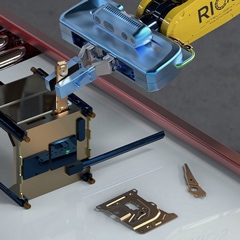

Pick and Place Automation

Repetitive tasks like assembly, or picking and packing of products often require significant human capital to complete. However, as workforce shortages continue and automation costs shrink, many businesses are considering new ways of completing these tasks. New, dexterous AI-powered robots are making this possible. These robots can be configured to perform a wide variety of tasks, work in unstructured environments, and be deployed across a range of industries.

Automation Solutions

Shrink Systems Automation

(Also known as Autobaggers) – Automated bagging systems are used in a wide range of industries to package small parts, manuals, and finished goods. Bagging machines seamlessly integrate into your operations, through customized in-feeds and accessories. These machines scan, pack, seal and print labels directly onto bags for sorting and shipping. Our engineers will work with you to customize your bagging configuration to increase efficiency and output.

Automation Solutions

Void Fill Automation

Our void fill automation systems feature the most cost-effective, time-efficient foam-in-place packaging technology in the industry. On-demand foam or “foam-in-place” is made in real-time by combining two liquid foams in a bag or liner. The expandable foam packaging mixture rapidly surrounds the product creating a custom, protective mold. The foam-in-place system is ideal for high volume, medium to large applications that require cushioning or blocking and bracing to protect goods.

Automation Solutions

Weighing and Filling Automation

Weight-based controls are used in many industries to portion products for packaging. From cannabis to cereals, and medicines to meats, weighing and filling automation solutions are designed to help to ensure a consistent output every time.

These machines can weigh and fill pouches, bags, containers, cartons and cases from as little as 1 gram to 50 pounds with fill rates from 5 to 200 dispenses per minute.

Automation Solutions

Wrapping Automation

Once pallets are loaded, clear film or stretch wrap is commonly applied to stacked items to prevent shifting. Automated wrapping systems not only makes this process faster and more consistent, they also stretch the film to make better use of the material making them a fast, versatile and efficient solution for many businesses.

Products and Automation Solutions

-

Blocking and Bracing

Blocking and Bracing

Product

Blocking and Bracing

Prevent unwanted or damaging movement, while your products are in transit, with blocking and bracing. DCP International offers an array of air, paper, engineered foam, and pulp packaging solutions to help lock-in-place and cushion your product inside the box and in transit.

-

Corrugate Containers

Corrugate Containers

Product

Corrugate Containers

Corrugated cartons and products are a staple of product packaging for good reason. It is a relatively inexpensive, easy-to-use, recyclable product that can be cut to about any size or shape imaginable. These items can be custom designed or bought “off the shelf” in hundreds of stock sizes.

-

Cushioning

Cushioning

Product

Cushioning

Add stacking strength to any carton or container with corrugated partitions. Corrugated partitions are used in the packaging of various items including larger, heavier items, and also can be used to help support displays.

-

Interleaving

Interleaving

Product

Interleaving

When stacking items inside of a box, you run the risk of scratching, shifting and marring during the shipping process, especially if you don’t have the proper packaging. Interleaving protects your packaged goods, and we know just the right interleaving material matters to keep your product protected. With a wide range of solutions, DCP International can provide the proper stability, cushioning or surface protection for your needs.

-

Mailing/Bagging

Mailing/Bagging

Product

Mailing/Bagging

With e-commerce booming, more and more businesses are needing mailing and bagging packaging. Our diverse line of mailing and bagging solutions lets us help get your product ready for shipping. From stock and custom mailer products to automated systems we have the solutions that deliver.

-

Shrink Systems

Shrink Systems

Product

Shrink Systems

Give your products the look and protection they deserve with shrink sleeve packaging. Shrink sleeves are designed to fit cleanly around your product, giving you 360 degrees of tamper-evident protection and printing. Shrink sleeves are durable to wear and tear, and can easily be perforated to make them easy to remove.

-

Surface Protection

Surface Protection

Product

Surface Protection

Creating a product takes time, effort and money. The last thing you need when your job is done is for a scratch or dent to ruin your product and jeopardize your reputation. DCP International can help you protect your surface and shield it from all types of encounters in its journey from creation to consumer. Our solutions are tailored to your needs, whether you have to protect the surface, keep your edge or protect those in-between places.

-

Thermal Ribbons

Thermal Ribbons

Product

Thermal Ribbons

Your product’s packaging displays essential information. From barcodes to logos to expiration dates and batch numbers, your product data must be easily legible, identifiable, and traceable throughout the life cycle of your product packaging. Thermal transfer ribbons enable high fidelity printing and durability on a range of media including shipping tags, crates, signs, frozen food packaging, machine parts, and electronics

-

Void Fill

Void Fill

Product

Void Fill

Space inside a box may seem like a good thing, but too much space can allow products to shift and become damaged. That’s why it’s important to use appropriate void fill, to limit movement inside the box when shipping products. DCP International offers efficient and easy-to-use solutions whether you require an off-the-shelf material or On-Demand systems to integrate into your packaging line.

-

Wrapping

Wrapping

Product

Wrapping

Wrapping processes like flow wrapping, encapsulate products in a thin layer of clear or printed film. This film is sealed to protect and contain contents. In some cases heat is applied to shrink the film, to minimize product shifting within the package and minimize the “tails” on the product.

-

Blocking and Bracing Automation

Blocking and Bracing Automation

Automation Solutions

Blocking and Bracing Automation

Fragile items, surface-critical parts, and heavy equipment are especially prone to freight-related damage. That’s why Pioneer works with a range of on-demand air, paper and foam packaging systems that are designed to protect against in-box or in-crate movement. Pioneer’s expert packaging team can help you to identify a solution that is cost-effective, and helps to prevent costly freight-related damage.

-

Cohesive Packaging Automation

Cohesive Packaging Automation

Automation Solutions

Cohesive Packaging Automation

Whether your business packages and ships ecommerce goods to consumers, or industrial parts for shipping and storage; cohesive packaging is an intelligent, cost-effective and versatile solution. Pioneer works with the widest line of cohesive materials and equipment in the industry, and can provide complete cohesive automation systems to increase your packaging efficiency.

-

Cushioning Automation

Cushioning Automation

Automation Solutions

Cushioning Automation

Whether you are shipping fragile items, surface-critical parts, or heavy equipment, we know that protecting your products from damage is important. That’s why Pioneer works with a range of on-demand air, paper and foam packaging systems, designed to meet the challenges of your business. We can help you to identify a solution that is cost-effective, and helps to prevent costly freight-related damage.

-

Carton/Tray Erector Automation

Carton/Tray Erector Automation

Automation Solutions

Carton/Tray Erector Automation

User-friendly, efficient, cost-effective case erecting and tray forming solutions are designed to increase your production’s productivity. We offer several machine options, including corrugated boxes, and end of line processes. Case erectors models are available for low, mid and high-speed production rates, operating at speeds up to 35 boxes per minute. These machines can help automate your production line or greatly improve your existing systems.

-

Mailing/Bagging Automation

Mailing/Bagging Automation

Automation Solutions

Mailing/Bagging Automation

Automated bagging systems are used in a wide range of industries to package small parts, manuals and finished goods. Bagging machines seamlessly integrate into your operations, through customized in-feeds and accessories. These machines scan, pack, seal and print labels directly onto bags for sorting and shipping. Our engineers will work with you to customize your bagging configuration to increase efficiency and output.

-

Pick and Place Automation

Pick and Place Automation

Automation Solutions

Pick and Place Automation

Repetitive tasks like assembly, or picking and packing of products often require significant human capital to complete. However, as workforce shortages continue and automation costs shrink, many businesses are considering new ways of completing these tasks. New, dexterous AI-powered robots are making this possible. These robots can be configured to perform a wide variety of tasks, work in unstructured environments, and be deployed across a range of industries.

-

Shrink Systems Automation

Shrink Systems Automation

Automation Solutions

Shrink Systems Automation

(Also known as Autobaggers) – Automated bagging systems are used in a wide range of industries to package small parts, manuals, and finished goods. Bagging machines seamlessly integrate into your operations, through customized in-feeds and accessories. These machines scan, pack, seal and print labels directly onto bags for sorting and shipping. Our engineers will work with you to customize your bagging configuration to increase efficiency and output.

-

Void Fill Automation

Void Fill Automation

Automation Solutions

Void Fill Automation

Our void fill automation systems feature the most cost-effective, time-efficient foam-in-place packaging technology in the industry. On-demand foam or “foam-in-place” is made in real-time by combining two liquid foams in a bag or liner. The expandable foam packaging mixture rapidly surrounds the product creating a custom, protective mold. The foam-in-place system is ideal for high volume, medium to large applications that require cushioning or blocking and bracing to protect goods.

-

Weighing and Filling Automation

Weighing and Filling Automation

Automation Solutions

Weighing and Filling Automation

Weight-based controls are used in many industries to portion products for packaging. From cannabis to cereals, and medicines to meats, weighing and filling automation solutions are designed to help to ensure a consistent output every time.

These machines can weigh and fill pouches, bags, containers, cartons and cases from as little as 1 gram to 50 pounds with fill rates from 5 to 200 dispenses per minute. -

Wrapping Automation

Wrapping Automation

Automation Solutions

Wrapping Automation

Once pallets are loaded, clear film or stretch wrap is commonly applied to stacked items to prevent shifting. Automated wrapping systems not only makes this process faster and more consistent, they also stretch the film to make better use of the material making them a fast, versatile and efficient solution for many businesses.

Ready to get started?

Find out more about our capabilities and how we can help you.

OUR TRUSTED PARTNERS

Brands