Providing End of Line Packaging Solutions

DESIGNED TO INCREASE PRODUCTION AND REDUCE LABOR COSTS

At DCP International we know packaging automation. We offer a broad line of automation solutions that include case erectors, tray formers, case sealers, case packers, tray loaders, and pick & place and robotic palletizers. These solutions have been successfully installed for a diverse range of industries including food, cannabis, beverage, automobile, apparel, health, beauty, printing, pharmaceutical and consumer electronics.

An Automated Solutions Program Specific To Your Needs

Not sure where to start? No problem, our team of experts can help identify the best options for your company.

We know that packaging automation can be vitally important in overcoming space, labor and quality challenges. Add consistency, quality, and higher throughputs with automated solutions. Do you want to learn more? Explore your options below.

Products and Automation Solutions

Automation Solutions

Automatic Weighing and Dispensing

Automatic weigh filling machines are useful for almost every production need, accuracy requirement, space constraint and budget. These machines ensure ease of use, sanitation and serviceability. They can weigh and fill pouches, bags, containers, cartons and cases from as little as 1 gram up to 50 pounds and fill from 5 to 200 dispenses per minute. Automatic weighing and dispensing machines can easily integrate with other auxiliary machines including vertical form fill and seal machines, horizontal form fill and seal machines, pre-made pouch filling machines and container filling machines.

Automation Solutions

Bubble On-Demand

Bubble wrap has long been a staple in protecting and shipping goods, however with the costs for dimensional freight on the rise, and storage space in many businesses at a premium, people are seeking alternative solutions. Bubble on-demand systems convert high-quality films into inflatable cushions of air. This cushioning not only provides superior product protection, it’s also viewed as a more premium packaging by consumers – increasing the perceived product value of the items it’s protecting.

Automation Solutions

Cappers

Pioneer works with a range of automatic capping machines engineered for medium to high-speed requirements, and they are ideally suited for the snack food, confectionery, beverage, pharmaceutical and cannabis industries. Cappers offer leak guarding and tamper evidence while preserving freshness and prolonging shelf life. They accommodate many container sizes and can meet production rates from 10 to 150 cycles per minute depending on the specifics.

Automation Solutions

Carton Erectors

User-friendly, efficient, cost-effective case erecting and tray forming solutions are designed to increase your production’s productivity. We offer several machine options, including corrugated boxes, and end of line processes. Case erectors models are available for low, mid and high-speed production rates, operating at speeds up to 35 boxes per minute. These machines can help automate your production line or greatly improve your existing systems.

Automation Solutions

Closure and Tape

Automating your case sealing process can greatly increase productivity and reduce manual repetitive labor. Pioneer offers several different case sealing solutions. These machines are engineered to work directly with your automatic forming machines, to form and glue trays for operators in virtually any industry where a tray with a lid is needed. Once erected and filled, corrugated boxes, cases, and trays, are tightly sealed with hot glue or tape.

Automation Solutions

Cohesive Packaging

Whether your business packages and ships ecommerce goods to consumers, or industrial parts for shipping and storage; cohesive packaging is an intelligent, cost-effective and versatile solution. Pioneer works with the widest line of cohesive materials and equipment in the industry, and can provide complete cohesive automation systems to increase your packaging efficiency.

Automation Solutions

Flow Wrappers

We offer automatic flow wrapping machines to fit your budget, production rate and floor plan. Perfect for automatic bagging and product loading, our automatic flow wrapping machines can fill products that vary in length and bulk density. You’ll maximize production, minimize product and film waste and reduce maintenance costs

Automation Solutions

Foam in Place

Our machines and systems feature the most cost-effective, time-efficient foam-in-place packaging technology in the industry. On-demand foam or “foam-in-place” is made in real-time by combining two liquid foams in a bag or liner. The expandable foam packaging mixture rapidly surrounds the product creating a custom, protective mold. The intuitive equipment design and responsive controls simplify the packaging process, reduce cost and increase productivity.

Automation Solutions

Liquid Fill

Packaging liquids into containers takes precision, to ensure end products are clean, consistent – and in many cases child safe. Pioneer works with manufacturers in a range of industries to match automated liquid filling and sealing solutions with their end use. From lines capable of filling temperature-sensitive products, or adjusting to various size and container outputs, Pioneer can help you to identify the right solution for your needs.

Automation Solutions

Mailing/Bagging

Automated bagging systems are used in a wide range of industries to package small parts, manuals and finished goods. Bagging machines seamlessly integrate into your operations, through customized in-feeds and accessories. These machines scan, pack, seal and print labels directly onto bags for sorting and shipping. Our engineers will work with you to customize your bagging configuration to increase efficiency and output.

Automation Solutions

Pallet Stackers

Once products are packaged into cartons, trays, or jugs they are often placed on pallets according to a prescribed pattern. This precise stacking balances loads and prevents items from shifting or crushing. Automated palletizers are designed to streamline pallet stacking, while also eliminating human error and preventing workplace injury.

Automation Solutions

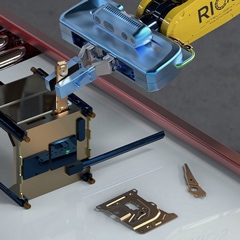

Pick and Pack Automation

Repetitive tasks like assembly, or picking and packing of products often require significant human capital to complete. However, as workforce shortages continue and automation costs shrink, many businesses are considering new ways of completing these tasks. New, dexterous AI-powered robots are making this possible. These robots can be configured to perform a wide variety of tasks, work in unstructured environments, and be deployed across a range of industries

Automation Solutions

Pre Roll Joint Packaging Machine

As the legalization of marijuana grows, so too does the demand for legal cannabis products. To keep pace with demand, and ensure consistency in their output, many cannabis businesses are turning to automated pre roll solutions. These machines are designed to automatically weigh, fill, twist and trim up to 4,000 pre-rolled cones per hour, increasing productivity and profitability.

Automation Solutions

Shrink Automation

Automated shrink systems are designed to apply heat to specially designed films, so that they conform neatly to the items being packaged. These flexible systems can be configured to accommodate a variety of packaging speeds and sizes, and work with other common production equipment (center folders, friction feeders, pick and place feeders, separating conveyors, combiners, checkweighers…and more).

Automation Solutions

Vertical Fill Form and Sealing Equipment

Our family of vertical bagging machines includes models for both mid-range and high-speed packaging and small or large bag sizes. We engineer our vertical form fill and seal machines to seal a wide variety of film types, structures and styles. We have installed hundreds of vertical form fill and seal machines around the world for a variety of products including snack food packaging, chocolate packaging, vegetable packaging, meat packaging, pet food packaging, cannabis packaging, pharmaceutical packaging, medicinal packaging, and frozen food packaging.

Automation Solutions

Weighing and Filling

Weight-based controls are used in many industries to portion products for packaging. From cannabis to cereals, and medicines to meats, weighing and filling automation solutions are designed to help to ensure a consistent output every time.

These machines can weigh and fill pouches, bags, containers, cartons and cases from as little as 1 gram to 50 pounds with fill rates from 5 to 200 dispenses per minute.

Products and Automation Solutions

-

Automatic Weighing and Dispensing

Automatic Weighing and Dispensing

Automation Solutions

Automatic Weighing and Dispensing

Automatic weigh filling machines are useful for almost every production need, accuracy requirement, space constraint and budget. These machines ensure ease of use, sanitation and serviceability. They can weigh and fill pouches, bags, containers, cartons and cases from as little as 1 gram up to 50 pounds and fill from 5 to 200 dispenses per minute. Automatic weighing and dispensing machines can easily integrate with other auxiliary machines including vertical form fill and seal machines, horizontal form fill and seal machines, pre-made pouch filling machines and container filling machines.

-

Bubble On-Demand

Bubble On-Demand

Automation Solutions

Bubble On-Demand

Bubble wrap has long been a staple in protecting and shipping goods, however with the costs for dimensional freight on the rise, and storage space in many businesses at a premium, people are seeking alternative solutions. Bubble on-demand systems convert high-quality films into inflatable cushions of air. This cushioning not only provides superior product protection, it’s also viewed as a more premium packaging by consumers – increasing the perceived product value of the items it’s protecting.

-

Cappers

Cappers

Automation Solutions

Cappers

Pioneer works with a range of automatic capping machines engineered for medium to high-speed requirements, and they are ideally suited for the snack food, confectionery, beverage, pharmaceutical and cannabis industries. Cappers offer leak guarding and tamper evidence while preserving freshness and prolonging shelf life. They accommodate many container sizes and can meet production rates from 10 to 150 cycles per minute depending on the specifics.

-

Carton Erectors

Carton Erectors

Automation Solutions

Carton Erectors

User-friendly, efficient, cost-effective case erecting and tray forming solutions are designed to increase your production’s productivity. We offer several machine options, including corrugated boxes, and end of line processes. Case erectors models are available for low, mid and high-speed production rates, operating at speeds up to 35 boxes per minute. These machines can help automate your production line or greatly improve your existing systems.

-

Closure and Tape

Closure and Tape

Automation Solutions

Closure and Tape

Automating your case sealing process can greatly increase productivity and reduce manual repetitive labor. Pioneer offers several different case sealing solutions. These machines are engineered to work directly with your automatic forming machines, to form and glue trays for operators in virtually any industry where a tray with a lid is needed. Once erected and filled, corrugated boxes, cases, and trays, are tightly sealed with hot glue or tape.

-

Cohesive Packaging

Cohesive Packaging

Automation Solutions

Cohesive Packaging

Whether your business packages and ships ecommerce goods to consumers, or industrial parts for shipping and storage; cohesive packaging is an intelligent, cost-effective and versatile solution. Pioneer works with the widest line of cohesive materials and equipment in the industry, and can provide complete cohesive automation systems to increase your packaging efficiency.

-

Flow Wrappers

Flow Wrappers

Automation Solutions

Flow Wrappers

We offer automatic flow wrapping machines to fit your budget, production rate and floor plan. Perfect for automatic bagging and product loading, our automatic flow wrapping machines can fill products that vary in length and bulk density. You’ll maximize production, minimize product and film waste and reduce maintenance costs

-

Foam in Place

Foam in Place

Automation Solutions

Foam in Place

Our machines and systems feature the most cost-effective, time-efficient foam-in-place packaging technology in the industry. On-demand foam or “foam-in-place” is made in real-time by combining two liquid foams in a bag or liner. The expandable foam packaging mixture rapidly surrounds the product creating a custom, protective mold. The intuitive equipment design and responsive controls simplify the packaging process, reduce cost and increase productivity.

-

Labelers

Labelers

-

Liquid Fill

Liquid Fill

Automation Solutions

Liquid Fill

Packaging liquids into containers takes precision, to ensure end products are clean, consistent – and in many cases child safe. Pioneer works with manufacturers in a range of industries to match automated liquid filling and sealing solutions with their end use. From lines capable of filling temperature-sensitive products, or adjusting to various size and container outputs, Pioneer can help you to identify the right solution for your needs.

-

Mailing/Bagging

Mailing/Bagging

Automation Solutions

Mailing/Bagging

Automated bagging systems are used in a wide range of industries to package small parts, manuals and finished goods. Bagging machines seamlessly integrate into your operations, through customized in-feeds and accessories. These machines scan, pack, seal and print labels directly onto bags for sorting and shipping. Our engineers will work with you to customize your bagging configuration to increase efficiency and output.

-

Pallet Stackers

Pallet Stackers

Automation Solutions

Pallet Stackers

Once products are packaged into cartons, trays, or jugs they are often placed on pallets according to a prescribed pattern. This precise stacking balances loads and prevents items from shifting or crushing. Automated palletizers are designed to streamline pallet stacking, while also eliminating human error and preventing workplace injury.

-

Pick and Pack Automation

Pick and Pack Automation

Automation Solutions

Pick and Pack Automation

Repetitive tasks like assembly, or picking and packing of products often require significant human capital to complete. However, as workforce shortages continue and automation costs shrink, many businesses are considering new ways of completing these tasks. New, dexterous AI-powered robots are making this possible. These robots can be configured to perform a wide variety of tasks, work in unstructured environments, and be deployed across a range of industries

-

Pre Roll Joint Packaging Machine

Pre Roll Joint Packaging Machine

Automation Solutions

Pre Roll Joint Packaging Machine

As the legalization of marijuana grows, so too does the demand for legal cannabis products. To keep pace with demand, and ensure consistency in their output, many cannabis businesses are turning to automated pre roll solutions. These machines are designed to automatically weigh, fill, twist and trim up to 4,000 pre-rolled cones per hour, increasing productivity and profitability.

-

Shrink Automation

Shrink Automation

Automation Solutions

Shrink Automation

Automated shrink systems are designed to apply heat to specially designed films, so that they conform neatly to the items being packaged. These flexible systems can be configured to accommodate a variety of packaging speeds and sizes, and work with other common production equipment (center folders, friction feeders, pick and place feeders, separating conveyors, combiners, checkweighers…and more).

-

Vertical Fill Form and Sealing Equipment

Vertical Fill Form and Sealing Equipment

Automation Solutions

Vertical Fill Form and Sealing Equipment

Our family of vertical bagging machines includes models for both mid-range and high-speed packaging and small or large bag sizes. We engineer our vertical form fill and seal machines to seal a wide variety of film types, structures and styles. We have installed hundreds of vertical form fill and seal machines around the world for a variety of products including snack food packaging, chocolate packaging, vegetable packaging, meat packaging, pet food packaging, cannabis packaging, pharmaceutical packaging, medicinal packaging, and frozen food packaging.

-

Weighing and Filling

Weighing and Filling

Automation Solutions

Weighing and Filling

Weight-based controls are used in many industries to portion products for packaging. From cannabis to cereals, and medicines to meats, weighing and filling automation solutions are designed to help to ensure a consistent output every time.

These machines can weigh and fill pouches, bags, containers, cartons and cases from as little as 1 gram to 50 pounds with fill rates from 5 to 200 dispenses per minute.

Ready to get started?

Find out more about our capabilities and how we can help you.

OUR TRUSTED PARTNERS

Brands